The loading characteristics of Starrco’s preassembled buildings are:

Snow Load: 30 PSF

Wind Load: 90 MPH

Floor Load: 50 PSF

When you need a preassembled portable building now, our quickship program has you covered. A quickship building can be at your site in as little as a week or two. Contact us for a quote & we will help you get everything ready for your new preassembled portable building.

Starrco’s pre-assembled buildings are designed to provide years of maintenance free service. The structural members are either aluminum or steel with a rust retardant finish. Walls, ceiling and floor have a solid impact resistant core with a durable aluminum or vinyl covered finish. Windows and sliding doors are aluminum finish, swing doors are commercial grade steel.

Jumpstart your facility with simple, solid preassembled buildings. Let us know what you’re looking for, and we’ll let you know how we can help.

The loading characteristics of Starrco’s preassembled buildings are:

Snow Load: 30 PSF

Wind Load: 90 MPH

Floor Load: 50 PSF

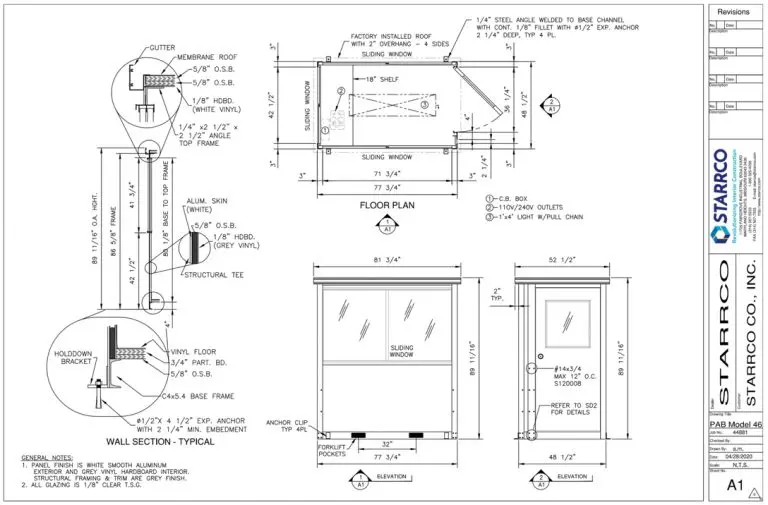

Structural members for corners are 3” x 3”, ¼” aluminum angle. Structural members between panels are 4” x 2½”, 3/16” aluminum “T” extrusion. Top frame will be 2 ½” x 2 ½”, 3/16” aluminum angle. All aluminum structural members will be 6063 alloy, T6 temper, painted with grey enamel finish.

Wall panels are a minimum ¾” thick sandwich construction. Exterior of panel is smooth white painted aluminum laminated to high density OSB board. Panel interior will be 1/8” gray vinyl covered hardboard. Panels will be caulked with a urethane sealant and fastened to structural members with plated screws.

Ceiling panels are a minimum ¾” thick sandwich construction. Interior of panel is 1/8” white vinyl covered hardboard laminated to high density OSB board. Top of panel will have an aluminum vapor barrier.

The building base will be 4” structural steel channels, welded, with stringers on maximum 24” centers. Base includes forklift pockets. Steel channels will be painted with a rust inhibitive paint. Sub-flooring is two layers of 5/8” OSB board with aluminum vapor barrier laminated underneath. Finished floor will be commercial grade seamless vinyl.

The roof will ship installed on the building. Installed roof consists of .060” EPDM membrane laminated to ceiling panels with aluminum gutters on all four sides.

Windows will be single sliding aluminum with locking device. Sliding sections are glazed with 1/8” clear tempered safety glass. All window framing is white painted aluminum finish.

Door will be a commercial grade 3068 20ga. steel with a 1/8” tempered safety glass window in top half. Door includes 1 ½ pair of 4 ½” x 4 ½” ball bearing hinges and a stainless steel key-in-knob lockset. Door will be mounted on a painted aluminum door frame with wool pile weatherstrip. Door is painted white.

Pre-wired electrical package includes one 125v duplex receptacle, one 230v single receptacle, fluorescent lighting, and one 125 amp circuit breaker box. All electrical components are UL listed and all wiring conforms to the National Electrical Code.