Modular grow rooms are an increasingly popular option for indoor cannabis cultivation. They offer a versatile and customizable solution that growers can adapt to meet their specific needs. You’ll want to consider several cost factors when setting up a modular grow room, from design and lighting to environmental controls. Follow our guide to determine your budget and the features you’ll need for your operations.

The structure is the primary cost of setting up a modular grow room. This includes the walls, ceiling, and flooring components that form the enclosure. The cost depends on the size of the room and the materials used for construction, though yearly rent can cost $50,000 or more. When searching for modular grow rooms for sale, prefabricated systems often offer easy installation and versatility but can vary in price depending on the brand and quality, with costs around $60,000.

Having separate rooms rather than an open concept space can prevent pests or fungus from spreading across your entire crop. Custom modular grow rooms can ensure you use suitable building materials and design, providing maximum protection for your crops.

Lighting is a crucial element of a modular grow room price. The lighting system you choose depends on your budget, the size of your grow room, and the types of plants you plan to grow. They generally cost around $120,000. Here are some of the most common lighting systems used in indoor grow rooms:

In addition to the initial cost of the lighting system, it’s important to consider the ongoing modular grow room costs, such as electricity usage and bulb replacement. HID lights tend to use more electricity and have a shorter life span than LED or CMH lights, so they may cost more in the long run. LED lights tend to be the most energy-efficient and have the longest life span, making them a popular choice for larger grow rooms.

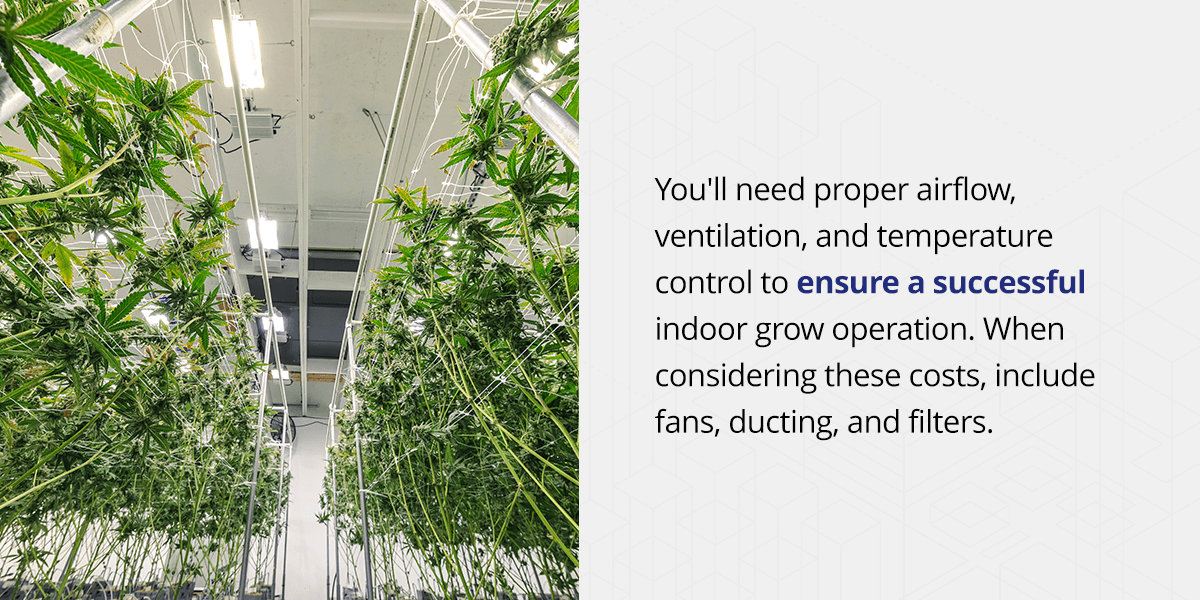

You’ll need proper airflow, ventilation, and temperature control to ensure a successful indoor grow operation. When considering these costs, include fans, ducting, and filters. Additionally, if the location requires heating, ventilation, and air conditioning (HVAC) upgrades, the costs of modular in-plant grow rooms can increase.

Proper ductwork and insulation can prevent air leaks and ensure the HVAC system works efficiently. Insulation can also help regulate the temperature and humidity in the grow room. And since carbon dioxide (CO2) is necessary for plant growth, some growers supplement the CO2 levels with systems that provide a steady supply to the plants.

Several types of irrigation and water systems are available for indoor growers to choose from, depending on their needs and budget.

Maintaining the optimal environment for plant growth requires monitoring and controlling temperature, humidity, and CO2 levels. Investing in environmental control systems, including sensors, controllers, and automation devices, can improve crop yields.

Setting up a cannabis production facility involves several areas or rooms, including a mother room, trim room, curing room, and flowering room. Here are some cost considerations and features to keep in mind when setting up each of these rooms:

A modular grow room is perfect for those who want to customize their grow environment to their specific needs. Customizing makes it easier for you to grow cannabis and saves time and resources. If you’re looking for an optimal cannabis growth environment, trust Starrco for high-quality modular grow room products and services. We’ll handle several aspects of your grow rooms, including structural elements, like wall panels and ceiling systems, and electricity, lighting, and environmental controls.

We manufacture and install modular grow rooms 75% faster than those built with traditional construction methods. That way, you can quickly adapt and continue growing with your industry’s demands. To get started, request a free quote today.