Modular cleanroom panel systems have become increasingly popular in a wide range of industries due to the numerous advantages they offer. From greater cost-effectiveness to cleanliness, modular cleanrooms provide various benefits over traditionally constructed cleanrooms. Applications like pharmaceuticals, biotechnology, aerospace, and health care can appreciate them for maintaining a specialized controlled environment with low contamination levels.

Here are some of the key advantages of using modular cleanroom panel systems:

Modular cleanroom panel systems are generally more cost-effective than traditional construction methods. Because they are pre-fabricated, they require less material and labor to install, which can result in significant cost savings for your facility. Also, the materials used in constructing these panel systems are relatively cheaper than traditional building materials — without sacrificing quality.

When installing traditional cleanrooms, you need specialized contractors to work the cleanroom into the blueprints, which means designing and running separate ductwork to manage airflow or even removing doors and windows. The process can take months and, therefore, be very costly.

Modular cleanroom wall panels cost a fraction of traditional cleanroom costs and provide a customized, clean environment. While the exact price depends on the standards you need to meet, teams can have your wall system up within a few days and allow your regular employees or contact labor to install the panels with easy-to-follow manufacturer instructions.

Modular cleanroom panel systems are designed to be easily reconfigured, allowing for greater versatility as your facility’s needs change. This means that you can quickly and easily modify your cleanroom’s layout, size, and configuration to accommodate new equipment, changing processes, or evolving regulations. The panels can be disassembled and reassembled in different ways to meet changing needs.

You can also expect versatility in your cleanroom panel designs. Some feature windows, while others include cutouts or openings for filters, lighting, and HVAC systems. Even the colors can be changed to signify essential features of your space, such as applications you’ll perform in your lab. Features you might include to meet your needs in a modular cleanroom include the following:

Versatility is one of the most crucial advantages of modular cleanroom panel systems since businesses grow and change. While you might meet current cleanliness standards, you can anticipate those standards changing in the future. You might also expect your operation to grow, and modular cleanroom panels allow you to easily relocate or expand the cleanroom without losing productivity or spending more money to move into a larger workspace.

Modular cleanroom panel systems offer more options for customization, allowing users to create a cleanroom that meets their specific needs and requirements. These cleanroom wall materials range from stainless steel and aluminum to polyvinyl chloride (PVC), allowing for greater durability, corrosion resistance, and cost-effectiveness. You can also choose cleanroom wall coverings designed to meet these environments’ strict cleanliness and hygiene requirements, with properties like anti-static and chemical resistance.

Installing modular cleanroom panel systems is generally quicker than traditional construction methods. Since the panels are pre-fabricated and pre-cut, installation can be completed in a fraction of the time compared to traditional construction, reducing downtime and minimizing disruptions to your operations. Additionally, no joint compound sanding, priming, or painting is required with modular cleanroom panels.

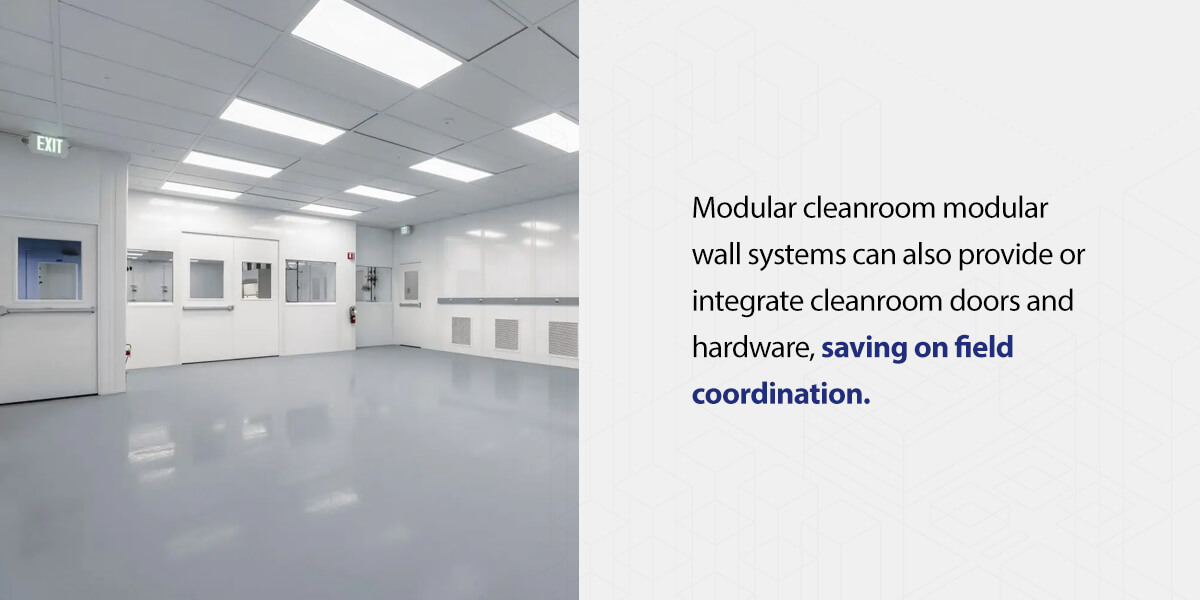

Modular cleanroom modular wall systems can also provide or integrate cleanroom doors and hardware, saving on field coordination. You’ll receive your doors and other features on-site, ready for installation.

Modular cleanrooms are designed to be easy to disassemble and reassemble, making it simple to replace or repair individual panels as needed. This means that maintenance can be performed quickly and efficiently, reducing downtime and minimizing disruptions to the production process.

In addition, modular cleanroom panel systems are designed with hygiene in mind. The panels are made of nonporous materials resistant to moisture and bacteria, making them easy to clean and sanitize. This ensures that the cleanroom remains in compliance with industry standards and regulations.

Overall, the easy maintenance of modular cleanroom panel systems helps to keep the cleanroom operating smoothly and efficiently, reducing the risk of contamination and ensuring that products are manufactured to the highest quality standards.

Modular cleanroom modular wall systems offer enhanced cleanliness compared to traditionally constructed cleanrooms. These systems have fewer seams and joints than traditional construction, which can harbor contaminants and require more frequent cleaning.

Cleanroom wall panel manufacturers design these systems with nonshedding materials that are easy to clean, preventing the accumulation of dust, particles, and other contaminants. Additionally, the panel systems are tightly sealed, creating an airtight environment that minimizes the risk of outside contamination.

The enhanced cleanliness of modular cleanrooms can lead to several benefits, including improved product quality, reduced risk of product recalls, and increased customer satisfaction. Modular cleanrooms with panel systems can be more cost-effective in the long run, as they require less frequent cleaning and maintenance than traditional cleanrooms.

Modular cleanroom panel systems offer a significant advantage in terms of energy efficiency over traditionally constructed cleanrooms. These systems are designed to meet the needs of modern industrial and scientific facilities while minimizing energy consumption and environmental impact.

One of the main reasons for the energy efficiency of modular cleanrooms is their airtight construction. Cleanroom wall panel manufacturers create tightly sealed systems to prevent air leakage, reducing the need for HVAC systems to work harder to maintain the required temperature, humidity, and cleanliness levels. This means less energy is needed to maintain the required conditions, resulting in lower energy bills and a reduced carbon footprint.

In addition to their airtight construction, modular cleanroom panel systems are also equipped with energy-efficient lighting, HVAC, and filtration systems. These systems are designed to maximize energy efficiency while maintaining optimal cleanliness and air quality levels in the cleanroom.

Modular cleanroom panel systems are designed to meet regulatory requirements and ensure compliance with industry standards. These systems are built using materials and components that meet specific safety and performance standards, making them suitable for use in industries requiring stringent cleanliness and environmental control.

Modular cleanroom panel systems are designed to be easily configured and modified to meet changing regulatory requirements. Cleanroom wall panel manufacturers create these systems with features that enhance compliance with industry regulations, such as HEPA filters for air filtration and advanced monitoring and control systems for maintaining a controlled environment.

Compared to traditionally constructed cleanrooms, modular cleanroom panel systems are easier to install, require less maintenance and are designed for efficient operation, resulting in lower energy costs. This makes them an attractive option for companies seeking to maintain compliance with regulations while keeping costs under control.

When you choose Starrco for modular cleanroom panel systems, you can expect expertly crafted designs that mirror or surpass on-site-built models. We outfit our modular cleanrooms with air filtration systems to prevent contamination from compromising your products and provide wall systems, electricity, flooring, lighting, and other applications using top-quality products.

To get started, request a free quote today.