Updated: 6-27-2023

Modular offices are a popular and rewarding choice for many organizations. But for organizations in manufacturing, industrial, and warehousing spaces, there’s a subcategory of modular offices that are particularly beneficial: modular in-plant offices.

Let’s talk about what a modular in-plant office is and how it can benefit your facility.

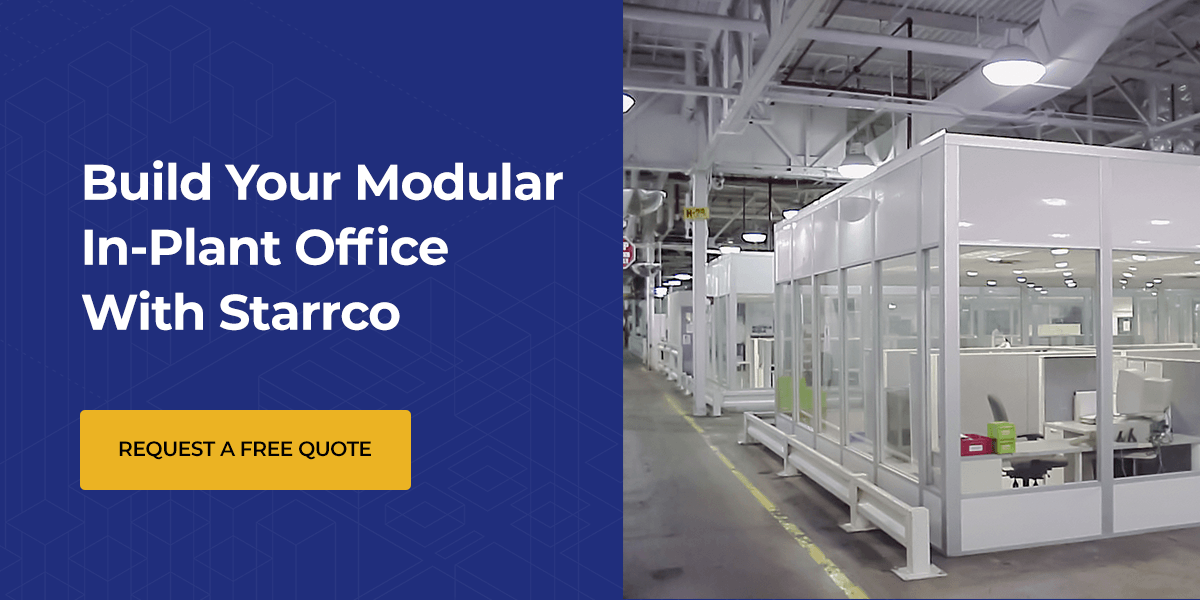

An in-plant office is an office system built within a warehouse or manufacturing facility in which it’s necessary to provide a separate space away from operational processes. Think of it like an office inside your existing building, but with the ability to turn the space into anything you need — whether that’s a break room, powder coating or paint room, or a security booth.

There’s more that goes on within warehouses, factories, and other industrial spaces than just a production line, and employees need a designated area for those activities.

There are two main construction methods to consider when building an in-plant office: traditional and modular construction. With traditional construction, you’d have to spend more time and resources during the planning and building processes. Those projects can take months, even a year, to complete.

Modular construction is a great alternative that can save your company time and money now and well into the future. It involves manufacturing standardized components (modules) off-site, then transporting them to be assembled on-site. Modular in-plant offices are the ideal solution for manufacturing and warehouse facilities because they’re easy to install, easy to modify, won’t break your budget, and function just as well as traditionally built ones.

Modular in-plant offices can be designed and manufactured to meet the demands of many applications. In most cases, plant supervisors need an administrative area that’s separate from the production floor. An in-plant office provides the ideal solution because it’s not so far from operations that they can’t respond when needed.

In-plant modular offices are also commonly used for:

Whatever tasks your manufacturing or warehouse facility needs a separate space for, in-plant modular offices can likely accommodate them.

Modular in-plant offices are constructed with high-quality components that function well, last a long time, and look great. They can be customized to meet your facility’s unique specifications, but some of the main components and features used for all are:

Now, why do you need a modular in-plant office? If you manage an industrial facility — whether it be manufacturing, factory, or warehouse — you need a clean and quiet space away from the production floor. For that, a modular in-plant office is an ideal solution. Here’s why.

If you’d like to build a modular in-plant office in your facility, choose Starrco. Our modular office solutions can provide the spaces you need to get administrative work done and keep your employees happy — all of which contribute to a healthier bottom line.

Our process begins with a consultation, where we get to know your needs and visit your warehouse or facility to examine your space. We’ll then create schematics for you to approve before we start fabrication at our facility. Once your in-plant office is ready, it’s shipped to your location. You can use our directions and CAD drawing to install it yourself, or have our team handle installation for you.

Request a free quote today.