Your search for the highest quality, the shortest project timeline, and the best value has led you to select a modular wall system for your construction project. And you’re not alone! But which type of modular system should you choose, and how do you determine the best approach when comparing open vs. closed modular construction?

Pre-manufactured construction is exploding in popularity. In fact, almost 60% of all construction happens off-site! That means more and more general contractors are turning to the controlled conditions and the skilled labor found in construction facilities that develop wall systems and complete room modules off-site today than ever before.

Knowing how to choose between open and closed modular construction methods can help you to save even more time and money. However, regardless of which process is best for your project, both prefabricated methods are built under controlled factory conditions using some of the same materials and designed to meet or beat the same codes and standards as conventionally built facilities.

Companies that use “closed modular construction” design, develop, and construct entire rooms off-site. The completed rooms include all the electrical wiring, plumbing, and HVAC runs needed for the room.

Large-scale projects like hospitals, apartments, and even houses benefit significantly from this type of efficient prefabrication process. There are no weather delays, and teams that work in controlled conditions are much more productive under optimal conditions. Customers can expect exceptional quality, too.

When a completed module arrives on the job site, it is hoisted and placed on the foundation, where the electrical, plumbing, and HVAC will be connected to the previous module. This process will continue until all modules are on-site and connected to the electrical panel, the water and sewer lines, and the furnace and AC units.

The closed construction process received its name because these integral components are installed and closed up at the manufacturing facility prior to delivery at the job site.

In most states, a project considered “closed construction” must be inspected by local authorities to verify that all construction meets local code requirements. These inspections typically take place at the manufacturing facility rather than on the job site.

Most of the work that goes into building a closed modular construction system occurs off-site. All components incorporated into the unit are manufactured and assembled in a controlled environment and undergo quality control checks throughout the construction process. Up to 90% of the construction work is done in this setting before the prefabricated structure is brought to the site.

Some of the core benefits associated with a closed modular construction approach include:

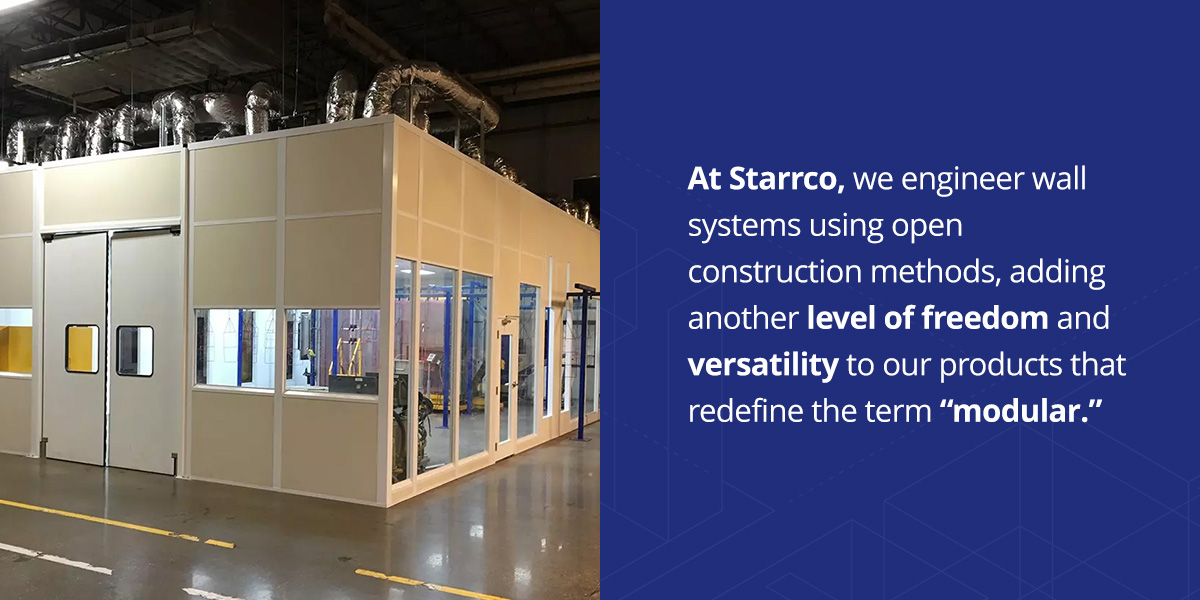

At Starrco, we engineer wall systems using open construction methods, adding another level of freedom and versatility to our products that redefine the term “modular.”

Closed modular systems are designed and developed off-site, and once the prefabricated module is in place, it’s permanent. Starrco modular wall systems deliver a simplified and more efficient method defined as “open construction” because the wall panels are solid and shipped separately with edges exposed.

Starrco panelized wall systems are also designed and developed to your specifications off-site. The added benefit is that our modular walls and partitions can be expanded, downsized, and even relocated without losing quality or engineering integrity. Because the panels are solid, no plumbing or electrical components are installed within the walls.

Open construction projects facilitated by Starrco marry the wall panels with durable weight-bearing studs. These studs run from floor to ceiling and can house electrical, data, and water supply lines covered by a snap-off cover. The snap-off covers allow for the easy inspection of each component while blending seamlessly into the design of the rest of the structure.

With open modular construction, none of the components are hidden, which means building officials can visually inspect all the components and utilities at the job site with ease. When the inspection is complete, the covers are snapped back on the studs, and the project is done.

Like closed modular construction units, all modular elements, such as the walls, frames, ceilings, and stairs, are manufactured off-site in a sheltered and controlled environment. Skilled engineers carefully monitor the manufacturing of Starrco modular components, which undergo stringent quality checks.

We custom design and manufacture each component to suit your specific needs and include vital infrastructure elements such as electrical, air conditioner, and HVAC units. We also take care of any painting or specialized finishes before transporting the modular system components to your site for installation.

Open modular construction has its perks, which include the following:

Open and closed modular construction both deliver a highly functional and exceptional quality product. Still, Starrco proudly manufactures systems built using open construction architecture because open construction simplifies the inspection process, allowing us to deliver a more versatile product to our clients.

As more inspectors become familiar with open modular construction, they will learn the method can significantly reduce the time associated with inspection. What’s more, open construction offers a more efficient build and maintenance process. Should you need any electrical or plumbing service in the future, all points of the system are easily accessed by removing the snap-off cover. This ensures the longevity and serviceability of your new modular building or office, protecting your investment well into the future.

Open modular construction is a fast, intuitive, and safe construction method for a range of building applications. If you’re considering a new project, but aren’t sure how to get started, contact the Starrco team at 800-325-4259 or request a free quote online today.